Exploring the Different Types of Electrical Wires and Cables

Any electrical system must have electrical wires and cables because they transport electrical current effectively and safely between locations. Knowing the many kinds of wires and cables and their intended applications is essential for guaranteeing the security and efficiency of the complete electrical system, whether you’re building a new home, installing wiring in a business, or working on industrial equipment. Ten major categories of electrical wires and cables are examined in this article along with their uses and the things to take into account when choosing the best wire for your project.

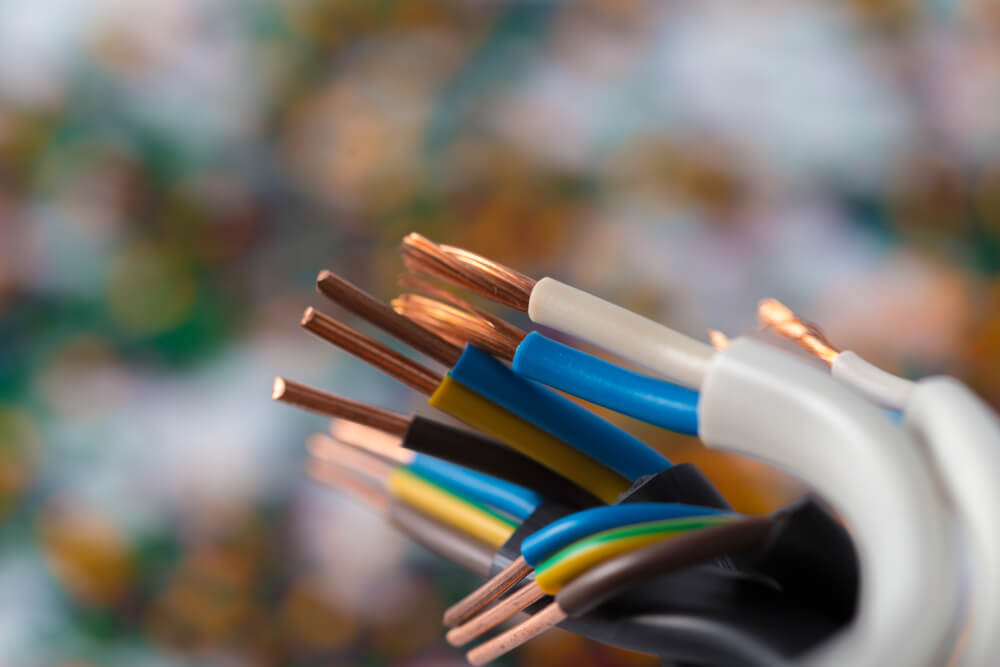

1. Cooper Wires

Because of its superior conductivity, copper is the most often used material for electrical wiring. Copper wire is perfect for electrical systems in homes, businesses, and industries because it has a lower resistance, which facilitates more efficient power flow. Copper wires offer endurance and dependability in electrical installations because they are strong, flexible, and corrosion-resistant. These wires are safer for long-term usage in many applications because they can withstand large currents with less heat buildup.

Copper wire types include:

- Solid copper wire: One copper strand is used to make this kind of wire. Electrical systems that need a steady, immobile connection, like outlets and lighting in homes, are the ones that use it the most. Although solid copper wire is very conductive, it is not flexible. It works best in situations where there won’t be a lot of bending or moving of the wire.

- Stranded copper wire: Far more flexible than solid copper wire because it is composed of multiple thin copper strands that have been twisted together. Because of its flexibility, it is perfect for use in machinery, electrical lines, and cars where the wire may bend or move.

- Tinned Copper Wire: Tinned copper wire has a thin layer of tin coating the copper, which helps protect against corrosion. This makes tinned copper a good choice for outdoor applications, such as in marine environments or areas exposed to humidity and moisture.

2. Aluminum Wires

In electrical installations, aluminum wires are frequently utilized instead of copper, especially where cost and weight are considerations. Although aluminum is significantly lighter and less costly than copper, a greater gauge is needed to carry the same electrical load due to its lower conductivity. Furthermore, aluminum is more likely than copper to oxidize, which could impair performance if improperly fitted.

Types of Aluminum Wires:

- Solid Aluminum Wire: Applications needing high voltage transmission, including large-scale electrical systems or overhead power lines, usually employ solid aluminum wire. It is inexpensive and lightweight, but because aluminum expands and contracts with temperature changes, installation must be done carefully to guarantee strong connections.

- Stranded Aluminum Wire: More flexible than solid aluminum wire because it is made up of many strands of aluminum that have been twisted together. Large commercial electrical systems frequently employ stranded aluminum, but like solid aluminum, it needs to be carefully maintained to prevent oxidation-related problems.

- Aluminum Wire from the AA-8000 Series: This contemporary type of wire has a trace quantity of copper, which enhances its flexibility and conductivity. Power distribution and other high-demand applications frequently employ the AA-8000 series because it provides a favorable trade-off between price and performance.

3. Twisted Pair Wires (Cat5, Cat6)

The objective of twisted pair wires is to facilitate communication and networking. To reduce electromagnetic interference, these cables are made up of copper wire pairs that have been twisted together. In order to provide effective signal transmission over long distances, the twisting helps preserve the integrity of the data being transferred.

- Cat5e and Cat6 wires. Cat5e cables: Two popular types of twisted pair cables used for Ethernet networking are appropriate for home networks and small business settings since they can manage data speeds of up to 1Gbps. Cat6 cables, on the other hand, are perfect for high-speed or commercial applications where a lot of data is transported because they can carry speeds of up to 10Gbps.

- Comparing Shielded and Unshielded STP vs. UTP Twisted Pair: To shield the signal from outside interference, shielded twisted pair (STP) cables have an extra layer of insulation. These are frequently utilized in settings like factories or data centers where there is a lot of electrical noise. Because they don’t have this extra layer, unshielded twisted pair (UTP) cables are more affordable and flexible, commonly used in residential applications.commonly used in residential applications.

4. Coaxial Cable

High-frequency transmissions, including those needed for radio, television, and the internet, are sent over coaxial cables. Coaxial cables are designed with a central conductor (often copper), an outer layer for insulation, a shield to guard against interference, and an insulating layer to avoid short circuits.

- Applications of Coaxial Cable: Coaxial cables are widely used in cable TV and internet installations due to their ability to transmit signals over long distances with minimal degradation. They are also used in CCTV systems, radio communications, and other applications where high-frequency signals need to be carried without interference.

5. Underground Cables (UF Wire)

Because underground feeder (UF) cables are made for direct burial applications, no extra protective conduit is required when installing them in the ground. Usually, these cables are used to power distant buildings where conventional overhead lines are not an option, as well as for outdoor lighting and irrigation systems.

- Benefits of Underground Wiring: By lowering the possibility of damage from environmental elements like storms, falling objects, or auto accidents, UF wires improve safety. They are perfect for places where safety and aesthetics are crucial, such parks, residential neighborhoods, or commercial buildings. Underground systems are more dependable and require less maintenance than overhead cable, although being more costly to construct.

- Installation Considerations: In order to properly install UF wire and shield it from outside harm, it must be buried at a certain depth. Subterranean cables must generally be positioned deep enough to prevent unintentional contact during excavation or landscaping, though installation rules differ by location.

6. Armored Cable (AC or BX Cable)

Often called AC or BX cable, armored cable is a kind of wiring in which the insulated conductors are encased in a metal protective sheath. In settings where the cable may be exposed to collision, abrasion, or other stressors, this layer of protection is intended to shield it from physical harm.

- Applications for Armored Cable: Armored cables are frequently utilized in commercial buildings, industrial settings, and locations like basements, garages, and warehouses where they may be subject to harm. By avoiding electrical fires brought on by physical damage to the wire, the metal sheath provides an additional degree of protection.

7. PVC Insulated Cable

In both residential and business settings, polyvinyl chloride (PVC) insulated cables are among the most often utilized wires. PVC insulation is appropriate for both indoor and outdoor applications due to its strength, flexibility, and resistance to UV radiation, moisture, and abrasion. Lighting, power circuits, and general electrical installations are just a few of the many uses for these wires.

- Advantages of PVC Insulated Cable: PVC has superior insulating qualities, which shield the cable from environmental dangers and electrical malfunctions. For many electrical applications, this kind of cable is a cost-effective choice because it is also less expensive than other insulating materials.

8. Thermoplastic Cables (Teflon)

Teflon-insulated thermoplastic cables, for example, have remarkable chemical and heat resistance. These cables are perfect for usage in places where the wiring may be exposed to harsh chemicals or solvents, or in high-temperature conditions like industrial settings.

- Applications for Thermoplastic Cables: These cables are frequently utilized in industrial, automotive, and aerospace settings where exposure to harsh chemicals and high temperatures are issues. Additionally, they are employed in specialized situations where durability is crucial, such as laboratories.

9. Silicone Cables

Flexible, heat-resistant, and able to tolerate high temperatures, silicone insulated cables are appropriate for use in electrical motors, heating systems, and automotive systems, among other uses. These cables are a flexible option for industries that need both heat resistance and suppleness because silicone can withstand extremely high temperatures without losing its elasticity.

- Applications for Silicone Cables: Silicone cables are frequently utilized in high-power applications, heating elements, and settings where exposure to heat or the elements could cause other materials to fail. They are also perfect for the automotive sector, where flexible and heat-resistant parts like wiring harnesses are essential.

10. Control Cables

Control cables are specifically designed to transmit control signals and data between various components of a system. These cables are used in industrial automation, factory production lines, HVAC systems, and various other machinery-based operations.

- Applications of Control Cables: These cables are used to connect sensors, actuators, and control systems in a variety of industries. They ensure that the correct data and commands are sent to and from machines, allowing for automation and efficient operations. Control cables are often shielded to prevent electromagnetic interference (EMI), ensuring that the signal remains intact even in industrial environments.